In today’s competitive manufacturing landscape, top firms have learned to integrate effective data strategies to get an edge on the market. Gathering masses of data in varying granularity has never been easier. Yet, as the cost of data continues to decline, many manufacturers find it difficult to extract meaning, and so miss out on potentially critical insights and value. Other data laggards have yet to implement smart data policies into their key processes, and thus forfeit the opportunity for deep analysis altogether.

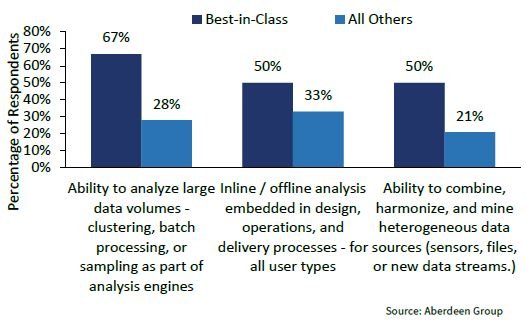

As shown above, best-in-class manufacturers command a lead over lagging companies in terms of their ability to analyze large data volumes, access analysis, and ability to extract meaning from data.

Data Consolidation

Data collection is not enough. Collecting data without a consolidated strategy-base is generally a waste of time, money and resources. Many companies find their data fragmented or otherwise disintegrated across separate systems. Extracting meaningful conclusions from fragmented information is daunting and often impractical because decisions made by modern manufacturing executives are rarely siloed within one business function. Rather, most decisions are either impacted by, or somehow affect related domains.

For example, high level decisions concerning supply chain management are greatly empowered by a holistic understanding of potential impact on finance and accounting. If data from these systems is disintegrated, a decision maker must go through the overwhelming process of defining, extracting, combining, and analyzing chunks of information in an attempt to paint a larger picture. Such a process can be highly discouraging and fosters avoidance or abandonment.

Firms that operate on an integrated data strategy, with one, unified system for analysis, enjoy an important advantage over their lackluster counterparts. Data consolidation is a must for any ambitious manufacturer and this can be accomplished with supply chain ERP solutions and implementation.

Analytical Culture

So, you’ve integrated a consolidated data strategy, now what? No amount of structured data can help your business if it goes ignored during the decision process. Best-in-class manufacturers understand and have installed data analysis into all business processes that have broader implications.

Creating an analytical culture starts at hiring. Top firms seek out candidates that have an analytical mind and understand the significance of data driven decision making. Data analysis and data driven thinking is a skill that must be learned and nurtured. Throwing untrained personnel into a data facing position is generally a recipe for disappointment.

Data Mobilization

Fingertip access to structured, real-time information is a successful formula for a data-driven company mindset. On-demand access to business analytics makes all the difference when facing an internal or customer inquiry. Running to the desktop computer or, worse yet, requesting a printout from the specific department is impractical in this mobile age.

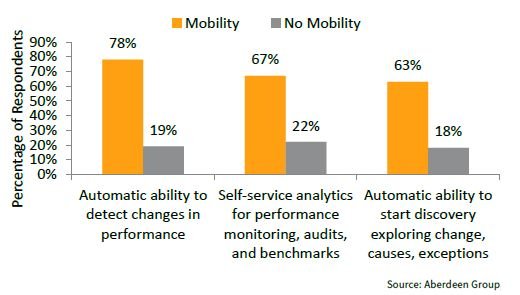

This is why top manufacturers make it a point to equip decision makers with appropriate mobile technology that allows them easy access to empowering business insights. The difference is staggering. The following chart compares mobility to non-mobility across three indicators:

As shown, mobile access to insights plays a decisive role in detecting performance changes, self analysis, and issue resolution. A mobile manufacturer has the upper hand over a non-mobile competitor.

Summary

The manufacturing industry is moving fast. Competition is at a high and firms that lag will pay a price. Data empowered manufacturers have insight into their businesses and markets, to which laggards are generally blind. This allows for a more responsive business model and more efficient operational flow.

Just collecting data is not enough. Employing smart data policies makes all the difference as time comes to make important business decisions when responding to pressing issues or opportunities for growth and improvement.